from Barton Gold Holdings Limited (isin : AU0000153215)

New High-Grade Assays Extend Tolmer Silver & Gold Zones

Barton expediting reconnaissance drilling to map extent of silver zone

HIGHLIGHTS

Dual high-grade silver and gold zones recently identified at the Tarcoola Gold Project's ( Tarcoola ) ‘Tolmer' prospect, with assay grades up to 17,600g/t Ag and 83.6g/t Au (respectively) 1

Additional reverse circulation (RC) drilling assays have extended high-grade silver within a shallow and broadening western ‘silver zone', with new significant assays including:

Hole ID | Interval | Including: |

TBM225 | 2m @ 111 g/t Ag from 63m metres* | |

TBM227 | 4m @ 1,417 g/t Ag from 9 metres | 1m @ 3,790 g/t Ag from 9 metres |

TBM228 | 23m @ 95 g/t Ag from 4 metres 14m @ 434 g/t Ag from 46 metres* | 1m @ 3,350 g/t Ag from 54 metres |

* Note - this assay interval also contains a high-grade gold result, see gold summary table below.

New RC drilling assay results have also extended high-grade gold within a shallow ‘gold zone' located ~1km east of the ‘silver zone', with new significant assays including:

Hole ID | Interval | Including: |

TBM221 | 5m @ 3.07 g/t Au from 16 metres | |

TBM222 | 5m @ 4.38 g/t Au from 49 metres | 1m @ 13.6 g/t Au from 52 metres |

TBM225 | 15m @ 1.07 g/t Au from 51 metres* | 4m @ 1.90 g/t Au from 51 metres |

TBM228 | 1m @ 3.05 g/t Au from 46 metres 3m @ 3.25 g/t Au from 54 metres* | 1m @ 7.50 g/t Au from 54 metres* |

* Note - this assay interval also contains a high-grade silver result, see silver summary table above.

Planning underway for expedited follow up drilling to map extent of western ‘silver zone'

ADELAIDE, AUSTRALIA / ACCESS Newswire / April 15, 2025 / Barton Gold Holdings Limited (ASX:BGD)(FRA:BGD3)(OTCQB:BGDFF) ( Barton or Company ) is pleased to announce further high-grade assays from the Tolmer prospect ( Tolmer ) at its South Australian Tarcoola Gold Project ( Tarcoola ), where recent assays have confirmed high-grade gold and silver mineralisation. 1

New assays from recent RC drilling have identified further shallow high-grade mineralisation in each of the ‘western silver' and ‘eastern gold' zones, extending both along their interpreted strike. 1

Commenting on Tolmer's latest high-grade assay results, Barton MD Alexander Scanlon said:

"Tolmer is fast becoming an exciting development prospect, with two shallow high-grade silver and gold zones emerging next to one another. The ‘eastern gold' zone has been extended 100 metres north, and the ‘western silver' zone appears to thicken and carry high-grade silver as it continues west. Also of interest, the best new silver intersection is only 25 metres west of our best silver result to-date of 6m @ 4,747 g/t Ag, and includes two intervals of high-grade gold over 3 g/t Au. We are now planning follow up drilling to map this out quickly."

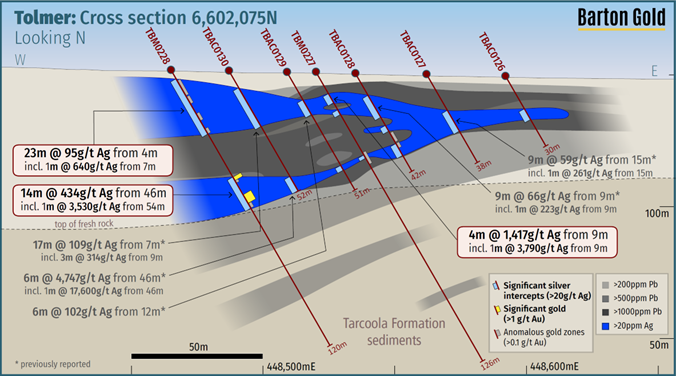

Emerging high-grade silver footprint

The assay results published on 27 March 2025 for Tolmer's ‘silver zone' indicate a distinct ‘silver dominant' mineralisation in association with a broad zone of anomalous lead, where high-grade silver occurs largely independent of gold. 2

The latest assays support this interpretation, with new intersections infilling and extending broad and high-grade silver mineralisation to the west within interpreted oxide and transitional zones. Broad zones of silver mineralisation commence from as shallow as 4 metres in hole TBM228.

High-grade gold has also been encountered within the highest grade silver in hole TBM228, which is interpreted to sit at the boundary of oxidised and fresh zones of mineralisation. It is unclear if any portion of this gold mineralisation is situated in fresh rock, and further evaluation is required to determine the potential for high-grade gold mineralisation complementing high-grade silver.

Planning for an expedited follow up geochemical and drilling program is now underway, with the objective to quickly map and drill test the potential western, northern and southern extensions of the ‘silver zone'. This will include the use of Barton's proven methodology for the application of Portable PPB's detectORE TM technology, rapid in-field analyses, and RC drilling guided by real-time Portable PPB's detectORE TM results.

Fig 1 (Section A) - Anomalous Ag-Pb zones & significant AC drilling intercepts (>100g-m Ag) 2

Key new silver assays from January and February 2025 RC drilling include:

Hole ID | Interval | Including: |

TBM216 | 7m @ 92 g/t Ag from 22 metres | 2m @ 272 g/t Ag from 22 metres |

TBM217 | 2m @ 66 g/t Ag from 16 metres | |

TBM225 | 2m @ 111 g/t Ag from 63 metres* | |

TBM227 | 4m @ 1,417 g/t Ag from 9 metres 2m @ 86 g/t Ag from 16 metres | 1m @ 3,790 g/t Ag from 9 metres |

TMB228 | 23m @ 95 g/t Ag from 4 metres 14m @ 434 g/ Ag from 46 metres* | 1m @ 3,530 g/t Ag from 54 metres* |

Table 1 - Key significant silver assays from January and February 2025 Tolmer RC drilling

* Note - this assay interval also contains a high-grade gold result, see gold assays in Table 2 below.

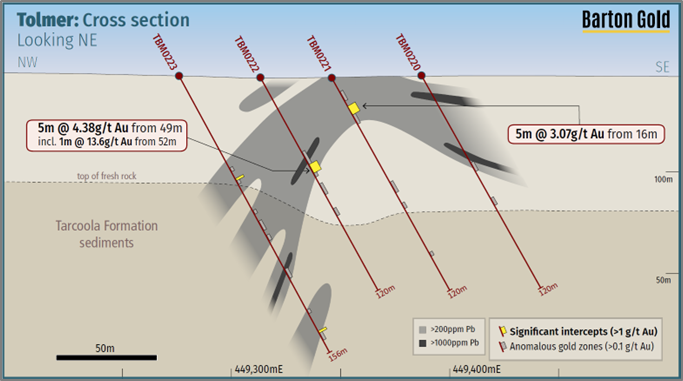

Extension of high-grade gold strike

Assays published on 27 August 2024 and 30 January 2025 for Tolmer's ‘gold zone' have identified one or more structures bearing high-grade gold mineralisation approximately 1km to the east of the ‘silver zone'. 3

New assays infill and extend this new gold zone, with broad and high-grade gold mineralisation intersected in new lines of RC drilling located between, and to the north of, prior high-grade assays.

This includes: 3

an intersection of 15m @ 1.07 g/t Au from 51 metres (TBM225) 50 metres south of TBM161 which previously reported the best intersection of 4m @ 24.6 g/t Au and 82.8 g/t Ag; and

neighbouring intervals of 5m @ 3.07 g/t Au from 16 metres (TBM221) and 5m @ 4.38 g/t Au from 49 metres (TBM222), 50 metres north of broad mineralisation in TBM180 and TBM181.

Barton anticipates that some follow up drill testing of the ‘gold zone' may be included in the expedited program to map and drill test the western ‘silver zone'. Further details will be confirmed in due course.

Fig 2 (Section B) - Anomalous gold zones and significant intercepts within alteration zones

Key new gold assays from January and February 2025 RC drilling include:

Hole ID | Interval | Including: |

TBM221 | 5m @ 3.07 g/t Au from 16 metres | |

TBM222 | 5m @ 4.38 g/t Au from 49 metres | 1m @ 13.6 g/t Au from 52 metres |

TBM225 | 15m @ 1.07 g/t Au from 51 metres* | |

TBM228 | 3m @ 3.25 g/t Au from 54 metres* 8m @ 1.11 g/t Au from 48 metres | 1m @ 7.50 g/t Au from 54 metres* |

Table 2 - Key significant gold assays from January and February 2025 Tolmer RC drilling

* Note - this assay interval also contains a high-grade silver result, see silver assays in Table 1 above.

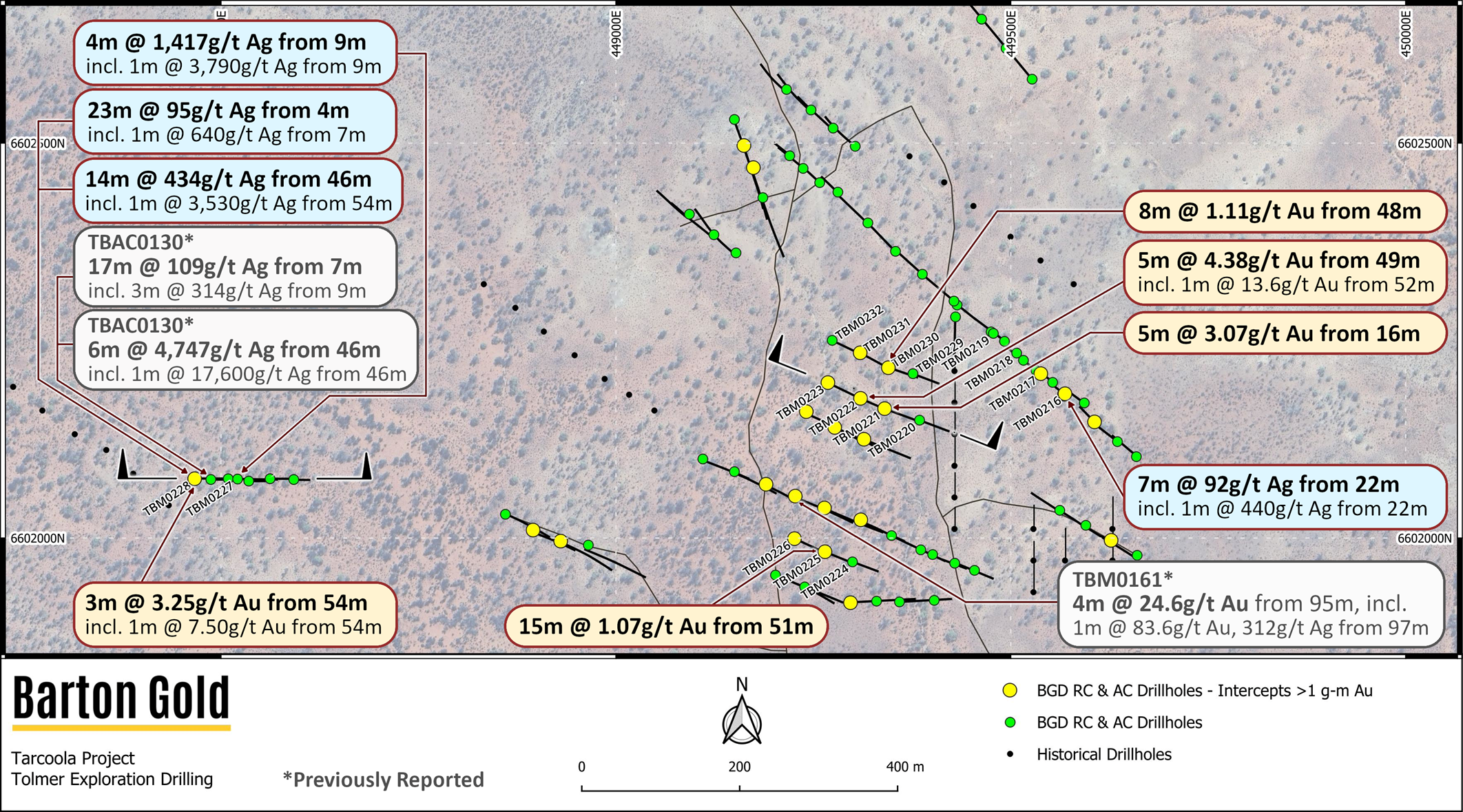

Dual Emerging Tolmer Gold and Silver Zones

An updated graphic depicting 2024 and 2025 AC and RC drill collars, along with significant gold and silver assay intersections received to date, is shown at Figure 3 below.

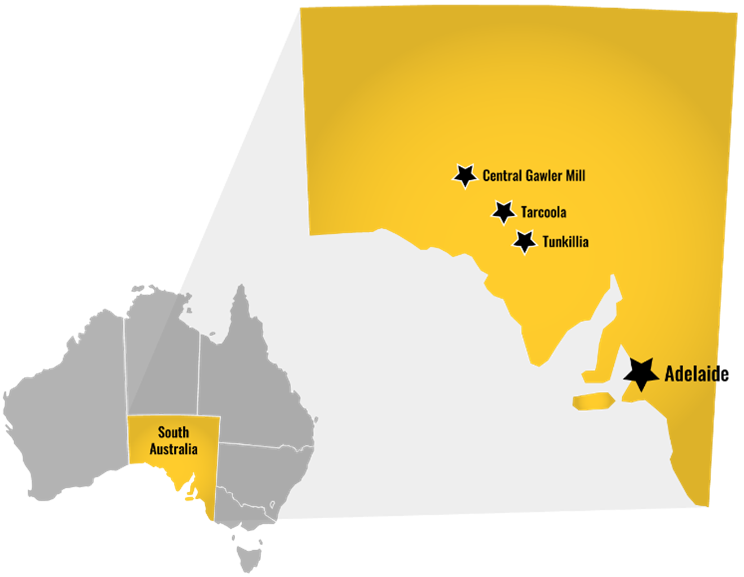

The Tolmer prospect is located ~5km west of Barton's Perseverance Mine (Tarcoola), ~130km southeast of Barton's fully permitted Central Gawler Mill, and ~70km northwest of the neighbouring Tunkillia project.

It's location provides multiple potential future commercialisation opportunities for blending of high-grade gold and silver mineralisation into Barton's existing Central Gawler Mill, or its future planned Tunkillia Mill.

Fig 3 - Tolmer plan map with recent RC and AC drill collars and key high-grade Au / Ag assays 4

Authorised by the Board of Directors of Barton Gold Holdings Limited.

For further information, please contact:

Alexander Scanlon | Jade Cook |

Competent Persons Statement

The information in this announcement that relates to Exploration Results for the Tarcoola Gold Project (including drilling, sampling, geophysical surveys and geological interpretation) is based upon, and fairly represents, information and supporting documentation compiled by Mr Marc Twining BSc (Hons). Mr Twining is an employee of Barton Gold Holdings Ltd and is a Member of the Australasian Institute of Mining and Metallurgy Geoscientists (AusIMM Member 112811) and has sufficient experience with the style of mineralisation, the deposit type under consideration and to the activity being undertaken, to qualify as a Competent Person as defined in the 2012 Edition of the "Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves" (The JORC Code). Mr Twining consents to the inclusion in this announcement of the matters based upon this information in the form and context in which it appears.

About Barton Gold

Barton Gold is an ASX, OTCQB and Frankfurt Stock Exchange listed Australian gold developer targeting future gold production of 150,000oz annually, with ~1.7Moz Au JORC Mineral Resources (64.0Mt @ 0.83 g/t Au), brownfield mines, and 100% ownership of the region's only gold mill in the renowned Gawler Craton of South Australia. *

Tarcoola Gold Project

Tunkillia Gold Project

Key Regional Infrastructure

|  |

Competent Persons Statement & Previously Reported Information

The information in this announcement that relates to the historic Exploration Results and Mineral Resources as listed in the table below is based on, and fairly represents, information and supporting documentation prepared by the Competent Person whose name appears in the same row, who is an employee of or independent consultant to the Company and is a Member or Fellow of the Australasian Institute of Mining and Metallurgy ( AusIMM ), Australian Institute of Geoscientists ( AIG ) or a Recognised Professional Organisation (RPO). Each person named in the table below has sufficient experience which is relevant to the style of mineralisation and types of deposits under consideration and to the activity which he has undertaken to quality as a Competent Person as defined in the JORC Code 2012 ( JORC ).

Activity | Competent Person | Membership | Status |

Tarcoola Mineral Resource (Stockpiles) | Dr Andrew Fowler (Consultant) | AusIMM | Member |

Tarcoola Mineral Resource (Perseverance Mine) | Mr Ian Taylor (Consultant) | AusIMM | Fellow |

Tarcoola Exploration Results (until 15 Nov 2021) | Mr Colin Skidmore (Consultant) | AIG | Member |

Tarcoola Exploration Results (after 15 Nov 2021) | Mr Marc Twining (Employee) | AusIMM | Member |

Tunkillia Exploration Results (until 15 Nov 2021) | Mr Colin Skidmore (Consultant) | AIG | Member |

Tunkillia Exploration Results (after 15 Nov 2021) | Mr Marc Twining (Employee) | AusIMM | Member |

Tunkillia Mineral Resource | Mr Ian Taylor (Consultant) | AusIMM | Fellow |

Challenger Mineral Resource | Mr Dale Sims (Consultant) | AusIMM / AIG | Fellow / Member |

The information relating to historic Exploration Results and Mineral Resources in this announcement is extracted from the Company's Prospectus dated 14 May 2021 or as otherwise noted in this announcement, available from the Company's website at www.bartongold.com.au or on the ASX website www.asx.com.au . The Company confirms that it is not aware of any new information or data that materially affects the Exploration Results and Mineral Resource information included in previous announcements and, in the case of estimates of Mineral Resources, that all material assumptions and technical parameters underpinning the estimates, and any production targets and forecast financial information derived from the production targets, continue to apply and have not materially changed. The Company confirms that the form and context in which the applicable Competent Persons' findings are presented have not been materially modified from the previous announcements.

Cautionary Statement Regarding Forward-Looking Information

This document may contain forward-looking statements. Forward-looking statements are often, but not always, identified by the use of words such as "seek", "anticipate", "believe", "plan", "expect", "target" and "intend" and statements than an event or result "may", "will", "should", "would", "could", or "might" occur or be achieved and other similar expressions. Forward-looking information is subject to business, legal and economic risks and uncertainties and other factors that could cause actual results to differ materially from those contained in forward-looking statements. Such factors include, among other things, risks relating to property interests, the global economic climate, commodity prices, sovereign and legal risks, and environmental risks. Forward-looking statements are based upon estimates and opinions at the date the statements are made. Barton undertakes no obligation to update these forward-looking statements for events or circumstances that occur subsequent to such dates or to update or keep current any of the information contained herein. Any estimates or projections as to events that may occur in the future (including projections of revenue, expense, net income and performance) are based upon the best judgment of Barton from information available as of the date of this document. There is no guarantee that any of these estimates or projections will be achieved. Actual results will vary from the projections and such variations may be material. Nothing contained herein is, or shall be relied upon as, a promise or representation as to the past or future. Any reliance placed by the reader on this document, or on any forward-looking statement contained in or referred to in this document will be solely at the readers own risk, and readers are cautioned not to place undue reliance on forward-looking statements due to the inherent uncertainty thereof.

JORC Table 1 - Tarcoola Gold Project

Section 1 Sampling Techniques and Data

Criteria | Commentary |

|---|---|

Sampling techniques Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc.). These examples should not be taken as limiting the broad meaning of sampling. Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. Aspects of the determination of mineralisation that are Material to the Public Report. In cases where ‘industry standard' work has been done this would be relatively simple (e.g. "RC drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay"). In other cases, more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g. submarine nodules) may warrant disclosure of detailed information | Sampling for Barton Gold's drilling program reported in this release was derived from RC drilling. Samples were collected via a cyclone mounted rotary splitter to derive both 1m samples with a nominal 2-4kg weight and 3m composite samples with a nominal 3kg weight. 3m composite samples were sieved to -1mm with a 250g sample presented for in-field analysis via the detectORE™ analytical method provided by Portable PPB Ltd & for analysis of a comprehensive multielement suite by pXRF. Selected 1m samples from anomalous 3m composite sample results were presented for fire assay analysis following drying, weighing, pulverising to -75um and deriving a 40g charge for analysis. Previous work Sampling during Barton Gold's drill programs at Tarcoola was obtained through reverse circulation (RC), Aircore (AC) and diamond drilling methods. Historic RC and diamond drilling methods were also used in drilling campaigns completed since the mid-1990s. Rotary air-blast (RAB) and aircore drilling has also been completed. These holes were used to guide interpretation but were not used for previous grade estimations or modelling of the results reported in the accompanying Announcement. The drilling program used a Metzke cone splitter (or similar) attached to the cyclone. One-metre splits were constrained by chute and butterfly valves to derive a 2-4kg split on the cyclone. Samples above 1m depth were not collected. Diamond core for drilling has been sawn in half using an automated core saw. Field duplicates were derived from using quarter core for the designated interval. Historic diamond core has been sawn in half or quarter using a core saw. Historic RC samples were collected using various splitting methods over the project's history. A splitter was generally used; however, spear samples were taken for a period of time in some holes. The sample preparation for drilling conducted in 2023 and 2024 of the one-metre sampling for Barton Gold's RC and diamond drill program was conducted by Bureau Veritas (Adelaide) using method FA1 where the 2-3kg split sample received at the laboratory is weighed, dried, crushed to 10mm, pulverized to 75 micron and split to provide a 40g sample for fire assay analysis. The sample preparation of the one-metre sampling for Barton Gold's 2021 RC drill program was conducted by Intertek Genalysis (Adelaide) using method SP1 where the 2-3kg split sample received at the laboratory is weighed, dried, crushed to 3mm, pulverized to 75 micron and split to provide a 50g sample for fire assay and adequate pulverized material for possible future multi-element analysis. Historically RC and diamond drilling samples were analysed by various laboratories by either fire assay or Aqua Regia digest, detection by atomic absorption spectrometry (AAS) or a Pulverise and Leach (PAL) process. 1 m RC or diamond samples were generally collected. |

Drilling techniques Drill type (e.g. core, RC, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc.) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc.). | The RC drilling by Barton Gold used a face-sampling 5 ¾" RC drilling techniques undertaken by Raglan Drilling using a Schramm T685 drilling rig with auxiliary compressor delivering a nominal 1000psi / 2200cfm air. Drill holes were surveyed using the Axis Champ orientation system at 5m intervals down hole. Drill holes were angled at a nominal -60 degrees and drilled to pre-planned depths and on occasion extended based on visual logging of drill chips. Previous work Historic drilling has taken place over numerous periods since the mid- 1980s as follows:

Since 2019 Barton has used Aircore, RC & Diamond drilling methods. |

Drill sample recovery Method of recording and assessing core and chip sample recoveries and results assessed. Measures taken to maximise sample recovery and ensure representative nature of the samples. Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. | Drilling recoveries were qualitatively described for each drilled interval in the field database along with an estimation of moisture content. In general recoveries were good, in the order of 30-40kg for each one-metre interval. Water was encountered in some drill holes and wet samples were collected from some intervals, although wet samples comprise <1% of sampling overall. No reduced sample weights were recorded with wet intervals and a review of results does not indicate contamination between adjacent samples. Samples submitted to the laboratory were weighed on a dry, as-received basis and reported along with assay results. No relationship between grade and recovery has been identified. Previous work Drilling recoveries prior to 2012 were not recorded for both RC chips and diamond core. Some earlier reports noted difficult drilling. Grenfell noted that care was taken to maximise recoveries and minimise contamination and wet drilling conditions were not often encountered. AngloGold noted no major problems with drilling conditions. TGL RC drilling programmes noted good recoveries, with weights of 30-40kg achieved in fresh material. Within the weathered zone, sample weights were more variable. Holes collared in the Quaternary overburden yielded poor or no recovery from the upper unconsolidated cover sequence, which does not host gold mineralisation. Diamond core recoveries were recorded by TGL. Local zones of core loss were noted in the oxide zone however core recoveries were generally good. The RC drilling was closely monitored by the site geologist to ensure optimal recovery and that samples were considered representative. Historically, HQ triple tube (HQ3) drilling was used for some holes to maximise core recovery. Re-entry holes were not triple-tubed as they were drilled straight into fresh bedrock. Drilling rates were controlled, and short drill runs were often used through the oxide zone to maximise core recovery. |

Logging Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc.) photography. The total length and percentage of the relevant intersections logged. | The RC drilling program electronically logged a number of parameters direct into a database including: Stratigraphy, lithology, weathering, primary and secondary colour, texture, grainsize, alteration type-style-intensity and mineralisation type-style-percentage. Previous work Logging practices varied over the project's history, however AngloGold attempted to standardize the logging by relogging holes in 2002. Approximately 17,000m of diamond and RC drilling and conversion of historical data into a consistent coding system. Some inconsistency in the logging is evident in the current database, however significant mapping has been completed in the pit which, in conjunction with the logging, provides a sound geological basis to prepare a Mineral Resource estimate. Logging from drilling is generally qualitative in nature. All diamond core and RC drilling has been geologically logged. |

Subsampling techniques and sample preparation If core, whether cut or sawn and whether quarter, half or all core taken If non-core, whether riffled, tube sampled, rotary split, etc. and whether sampled wet or dry. For all sample types, the nature, quality and appropriateness of the sample preparation technique. Quality control procedures adopted for all subsampling stages to maximise representivity of samples. Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling. Whether sample sizes are appropriate to the grain size of the material being sampled. | The RC drilling program used an Ox sampling system cone splitter mounted on the cyclone with one-metre splits constrained by chute and butterfly valves to derive a 2-4kg split on the cyclone. The majority (>99%) of samples were dry and when samples were wet they were recorded in the sampling records. Duplicate samples for QAQC purposes were derived by spearing of bagged residual sample material. Sample sizes are considered to be appropriate to the grain size and volume of the material being sampled. Previous work SADME (1964) - Diamond holes were quarter-cored by Grenfell. Aberfoyle (1979-1985) - Samples of open holes TP001-021 were collected in a PVC bag via a cyclone, and then split downto approximately 1.5kg. Newmex Exploration Limited/Tarcoola Gold Ltd (1987-1988) - RC samples from TRC001-TRC025 were collected over 1m intervals via a cyclone with an incorporated splitter. Approximately 3kg was collected for analysis. RC samples from TRC026-TRC138 were collected over 1m intervals and riffle split to collect a sample. The weight of the sample was approximately 2kg. BHP (1987-1989) - RC holes were sampled at 1m intervals with rock chips homogenized via a cyclone before being split and sampled. A 4m composite sample weighing approximately 2.5kg was initially submitted for analysis. The 1m samples were only submitted if the original 4m sample returned a value of >0.5 g/t Au. Diamond core was apparently half-cored, with samples generally taken at 1m intervals. Grenfell (1991-1993) - RC holes were sampled at 1m intervals were collected in full in plastic bags. The plastic bags were rolled several times to help ensure mixing prior to collecting a 1-2kg sample using a short plastic tube inserted diagonally several times into the material. A 4 m composite was initially submitted for analysis. 1m samples were only submitted if the original 4m sample returned a value of >0.3 g/t Au. Diamond core was apparently half-cored, with samples generally taken at 1m intervals. Grenfell (1995-1997) - RC holes were sampled at 1m intervals were collected in full in a plastic bucket, and then poured through a three-tier riffle splitter. Buckets were emptied through the splitter at 0.5m intervals. A 3kg sample was collected in a calico bag for assay, and the remaining sample collected in a large plastic bag. Poor sample recovery was apparently only noted within a small number of drillholes. Diamond core was apparently half-cored, with samples generally taken at 1m intervals. AngloGold (2001-2002) - RC holes were sampled at 1m intervals. Detail surrounding the RC subsampling techniques was not provided to CSA Global. Diamond core was apparently half- cored, with samples generally taken at 1m intervals. Subsampling is performed during the preparation stage according to the assay laboratories' internal protocols. During the RC drilling program primary samples were collected from a shute on the cyclone splitter. Field duplicates were obtained from a secondary shute on the splitter. To the best of the Competent Persons knowledge, no RC field duplicates were taken prior to 1995. After 1995, field duplicates have generally been inserted in the sample stream at a rate of one in every 20 samples. No data was provided for the AngloGold drilling program however (2001-2002). Results generally give confidence in sampling procedures . Sample sizes are considered to be appropriate to the grain size and volume of the material being sampled. |

Quality of assay data and laboratory tests The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. For geophysical tools, spectrometers, handheld XRF instruments, etc., the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. Nature of quality control procedures adopted (e.g. standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established. | Selection of RC samples for assaying for gold by fire assay is undertaken via in-field low-level gold analysis on 3m composite samples. The technique is a partial leach workflow called detectORE™ developed by CSIRO and provided by Portable PPB Ltd. The results are not considered sufficiently robust for public reporting of significant results but are suitable for reporting of below detection gold results (<0.02ppm Au) and selection of 1-metre samples for fire assay analysis. Additional samples for fire assay analysis for gold are also selected based on geological logging and supporting multielement analysis. 2-4kg splits were sent to Bureau Veritas in Adelaide for preparation and analysis using a 40g fire assay technique for gold. Bureau Veritas' FA1 method uses a 40 g lead collection fire assay with AAS finish to a 0.01 ppm detection limit. Multi-element analysis of RC drill samples is initially undertaken on 3-metre composites by portable XRF (pXRF), using an Evident Vanta unit. A 3-beam, 20 seconds per beam routine is performed on samples presented to the machine in plastic cups (pucks). Results from this preliminary analysis is used to determine intervals for laboratory analysis. QAQC (blanks, CRMs, duplicates) are routinely analysed and assessed as part of this workflow. Multielement analysis is undertaken on 1-metre drill samples by Bureau Veritas' MA102 method, applying a 4-acid digest with ICP-MS analysis and reporting a suite of 47 elements. Analysis of over-range silver (>300ppm Ag) is undertaken by Bureau Veritas' PF102 method, applying a fusion of the sample with sodium peroxide prior to dissolution in dilute hydrochloric acid and being presented for ICP-MS analysis. Statistical comparison between pXRF analyses and corresponding ICP-MS analyses has provided confirmed the integrity of the pXRF analyses with acceptable statistical correlations. The pXRF results are adequate for the reporting of geochemical thresholds and zones, but not individual interval results. No geophysical studies were used in this latest drilling program. Barton Gold's RC drilling program included a comprehensive QAQC component with Field Duplicates, Certified Standards (selection of OREAS CRM's considered most appropriate for expected grade and composition) and coarse blanks collectively inserted at ratio of approximately 1 in 37 primary samples. The sequencing of QC samples is tailored on the basis of preliminary (field) assaying to maximise the effect of QA. Additionally, the laboratories provided their internal QAQC which included check samples, CRM's, blanks and repeats. Analysis of the duplicate samples was variable but considered acceptable given the nature of gold mineralization associated with this project. Some significant variation was noted however this is considered consistent with the interpreted high nugget style of mineralisation. Bureau Veritas' analysis for gold using fire assay performed well with all batches falling within the +/-3SD test of the expected value for the given standards (3 OREAS CRM's). Previous work Analytical techniques have varied somewhat over the projects history and are summarised below. SADME (1964) - Diamond holes were sent to Amdel in Adelaide for analysis by Aqua Regia digest flame AAS with a 0.02 detection limit. Any samples returning grades >1 g/t Au were re-assayed by fire assay with an AAS finish. Aberfoyle Exploration (1985-1987) - Samples were submitted to Classic Laboratories in Perth for fire assay using a 50g charge. Newmex Exploration Limited, Tarcoola Gold Limited (1987- 1988) - Samples from TRC001-TRC025 were submitted to Genalysis in Perth for analysis using Aqua Regia digest and AAS finish after roasting to oxidise sulphides. Fire assay was carried out on all samples containing >1 g/t Au determined following Aqua Regia. Samples from TRC026-TRC138 were submitted to Classic Comlabs, Adelaide for analysis by fire assay. BHP Gold (1988-1991) - Samples were submitted to Amdel Laboratories in Adelaide for analysis. The analytical method is not known. Queens Road Mine/Grenfell Resources (1992-1994) - Samples were submitted to Amdel for digest by Aqua Regia (two parts hydrochloric acid to one-part nitric acid), followed by extraction into organic solvent (D.I.B.K.). A 50g subsample was then analysed by AAS with a 0.02 g/t Au detection limit. Grenfell Resources (1996-1998) - Earlier samples were submitted to Amdel for analysis by Aqua Regia digest with AAS finish. Any samples returning grades >1 g/t Au were re-assayed by fire assay with and AAS finish. Later holes were submitted to Aqua Regia digest with graphite furnace AAS. AngloGold, Gravity Capital Limited (2001-2002) - Earlier holes (up to TCRC0029) were submitted to Genalysis in Adelaide. Sample preparation was completed in Adelaide, and then sample analysis was completed in Perth via a 50g fire assaywith AAS finish (Method FA50/AAS). Later holes were submitted to Analabs in Perth for analysis by fire assay. Low Impact Diamond Drilling Services (2008) - Two core holes were submitted to Onsite Laboratory Services, Bendigo for analysis by 25g fire assay with AAS finish. Subsampling techniques are not known. Tunkillia Gold (2012) - Au analysis was completed by IntertekGenalysis in Adelaide, via a 50 g lead collection fire assay with AAS finish to a 0.005 ppm detection limit (Method FA50/AA). Tarcoola Gold (2016-2017) - Samples were dried at 90 ÌC to eliminate the impact of moisture on sample processing. After drying samples are crushed via a Boyd Crusher to <10mm in size then split through a rotary splitter to produce a sub-sample. The crusher is cleaned regularly and has barren bricks crushed between sample groups to prevent contamination. Analysis is through the pulverising and leach (PAL) process. This process reflects the site mill extraction process where: each process is pulverised in aqueous solution with cyanide bearing assay tabs and a collection of assorted sized ball bearings. Each sample is pulverised for an hour, resulting in an Au-CN complex bearing solution and remnant pulverised sample, and the pulverised material is 95% passing 75 microns. Following PAL processing, samples are decanted, centrifuged and prepared for analysis in an AAS with a solvent separation with a DIBK and residence time of 20 minutes. The sample is then aspirated through the AAS to produce a reading. Barton Gold (2020) - 2-4kg splits were sent to MinAnalytical in Perth for preparation and analysis using photon assay techniques for gold and ICPOES/MS for multielement geochemistry. The received samples used MinAnalytical's PAP3502R method for preparation which included weighing before drying and crushing to 3mm. A 500g charge was split for analysis using MinAnalytical's PAAU2 photon assay method for gold which is a fully automated technique designed for the analysis of ores. It uses high energy x-rays to excite the atoms so liberation from the surrounding material is not required. The ~500g single-use jars allows for bulk analysis with no chance of cross contamination between samples. Barton Gold (2021) - 2-4kg splits were sent to Intertek Genalysis in Adelaide for preparation and analysis using 50g fire assay techniques for gold and ICPOES/MS for multielement geochemistry. Whilst preparation and some fire assays were undertaken in Adelaide Intertek also sent some batches to their Perth laboratories for analysis. Intertek's FA50/OE04 method uses a 50 g lead collection fire assay with ICP-OES / MS finish to a 0.005 ppm detection limit. Multielement samples were analysed using Intertek's method 4A/MS48 which is a 4-acid digest followed by analysis using ICP-OES and MS for 48 elements. Barton Gold (2022-present) - 2-4kg splits were sent to Bureau Veritas in Adelaide for preparation and analysis using a 40g fire assay technique for gold. Bureau Veritas' FA1 method uses a 40 g lead collection fire assay with AAS finish to a 0.01 ppm detection limit. Selection of AC samples for assaying by fire assay is undertaken via in-field low-level gold analysis on 3m composite samples. The technique is a partial leach workflow called detectORE™ developed by CSIRO and provided by Portable PPB Ltd. The results are not considered sufficiently robust for public reporting but are suitable for selection of 1-metre samples for fire assay analysis. Additional samples for fire assay analysis for gold are also selected based on geological logging and supporting multielement analysis. Analysis of AC drill samples is initially undertaken on 3-metre composites by portable XRF (pXRF), using an Evident Vanta unit. A 3-beam, 20 seconds per beam routine is performed on samples presented to the machine in plastic cups (pucks). Results from this preliminary analysis is used to determine intervals for laboratory analysis. QAQC (blanks, CRMs, duplicates) are routinely analysed and assessed as part of this workflow. Multielement analysis is undertaken on 1-metre drill samples by Bureau Veritas' MA102 method, applying a 4-acid digest with ICP-MS analysis and reporting a suite of 47 elements. Statistical comparison between pXRF analyses and corresponding ICP-MS analyses has provided confirmed the integrity of the pXRF analyses with acceptable statistical correlations. The pXRF results are adequate for the reporting of geochemical thresholds and zones, but not individual interval results. No geophysical studies were used in this latest drilling program. Barton Gold's AC drilling program included a comprehensive QAQC component with Field Duplicates, Certified Standards (selection of OREAS CRM's considered most appropriate for expected grade and composition) and coarse blanks collectively inserted at ratio of approximately 1 in 37 primary samples. The sequencing of QC samples is tailored on the basis of preliminary (field) assaying to maximise the effect of QA. Additionally, the laboratories provided their internal QAQC which included check samples, CRM's, blanks and repeats. Analysis of the duplicate samples was variable but considered acceptable given the nature of gold mineralization associated with this project. Some significant variation was noted however this is considered consistent with the interpreted high nugget style of mineralisation. Bureau Veritas' analysis for gold using fire assay performed well with all batches falling within the +/-3SD test of the expected value for the given standards (3 OREAS CRM's). Historically, the amount of sampling and analytical QC data that has been collected has varied over the project's history. Limited sampling and analytical QC data is available to support drilling programs completed prior to 1992, which represents a relatively minor portion of the dataset. Between 1992 and 1994, the only meaningful QC data appears to be a comparison of spear and riffle split sampling results. No significant bias was noted between the methods. Between 1996 and 1998, standard results indicate no significant bias, and blank results suggest no issue with carry-over contamination. Field duplicate results reveal a reasonable amount of scatter, which implies poor sample precision, however no bias was noted. Check (umpire laboratory) assay results also revealed considerable scatter but no significant bias which further attests to the accuracy of the analytical data. It is understood no QC samples were submitted between 2001 and 2008. Tunkillia Gold used blanks to monitor carry-over contamination and no significant issues were detected. Field duplicates were used to assess sample precision, while CRMs were used to assess analytical accuracy. Some pulps were also sent to an umpire laboratory as a further check on analytical accuracy. Field duplicate results provide some confidence sample precision. The scatter which is observed is understandable given the moderate to high nugget effect evident at Tarcoola. The CRMs reasonably demonstrated the accuracy of the laboratory. Pulp repeats were higher than the original results, which did cause some concern however, given the CRM results the Competent Person had reasonable confidence in the accuracy of the primary laboratory. Tarcoola Gold collected field duplicates to monitor sample precision and submitted one main CRM to monitor analytical accuracy. The field duplicate results give some confidence in sample precision, with the scatter which is observed likely a consequence of the high-nugget nature of the mineralisation. Although only one CRM was used, no bias was noted. |

Verification of sampling and assaying The verification of significant intersections by either independent or alternative company |